Machine Bed

The stability and precision of the bed of màquina de tall làser directly affect the stability of cutting precision and cutting precision. It is essential for laser cutting machines.

Our bed with industry-leading plate welding, with high rigidity, stability, shock resistance. And perfect cooling, lubrication, dust removal system, so that the whole operation is stable, efficient and durable.

Funció de la màquina

1.The bed with steel plate welding method, annealing to eliminate the internal stress after processing, the process for the welding → annealing stress → roughing → vibration aging → semi-finishing → vibration aging → finishing, a better solution Due to welding and processing of the stress generated, which greatly improved the stability of the machine, long time to maintain the accuracy of the machine. If these stress relief treatments are not carried out, the bed will be deformed or cracked after a certain period of time. Affect the cutting accuracy.

2.Bed surface and the rack surface with a large gantry milling finishing, to ensure that the linear guide and the straightness and flatness of the rack, so as to ensure the operation of the machine and cutting accuracy.

3.Welding plate body plate, we use 20mm thickness, to ensure the weight of the bed, in the machine under high-speed operation, long-term to ensure the stability of the laser machine and high precision.

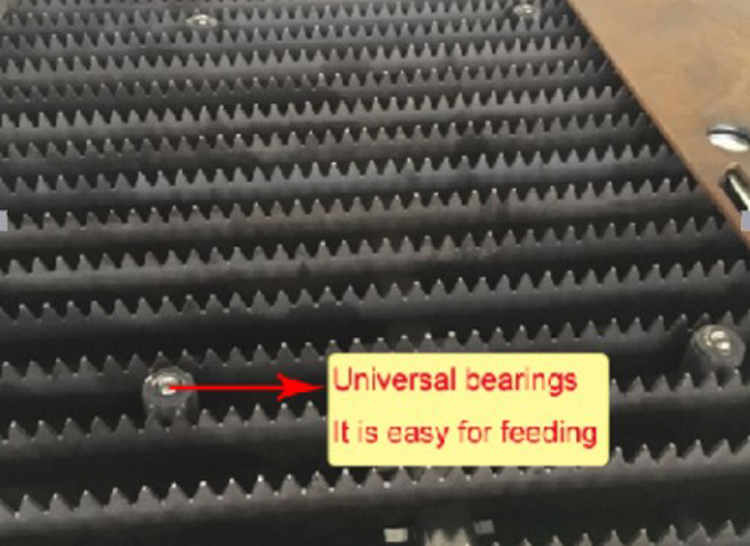

4.On the side of the bed, we installed universal bearings (Universal Bearings), to facilitate customer loading and unloading, saving up and down time.

5.In the bed discharge area, we also installed a number of rollers, to facilitate customer loading and unloading, and for human nature, save time.

6.Inside of the bed , we installed the dust collection system, customers simply install the fan, you can achieve dust, protect the environment.

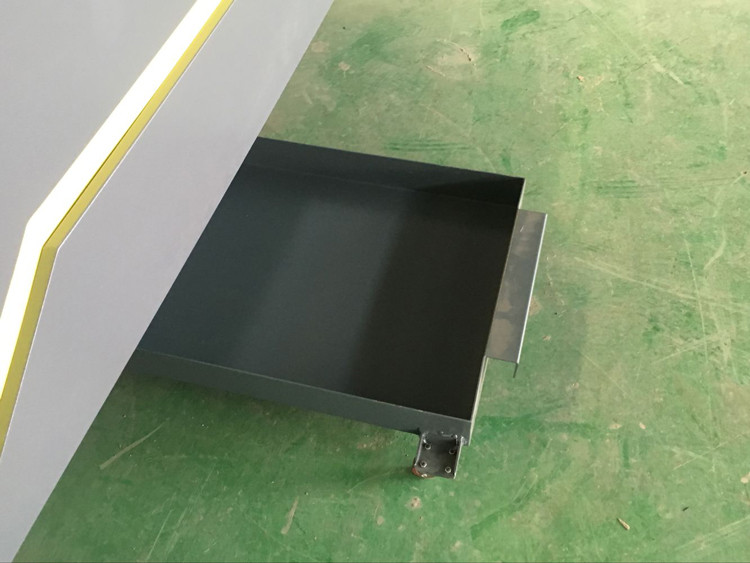

7.At the bottom of the bed, equipped with 3 material car, to facilitate customers to take material.

8.Bed at the bottom, the installation of six adjustable support, easy to adjust the level of machine tools to ensure the accuracy of cutting and long-term stability of the machine.

9.We installed the automatic oiling system, regularly to the bed gear rack and linear guide rails to add lubricating oil to ensure that the gear rack in a good lubrication to run the situation, improve the gear, rack life; to ensure the accuracy of the machine And stability.

Machine Beam

The beam body adopts the whole aluminum casting way, annealing to eliminate the internal stress after the processing, the process for the casting → annealing stress → roughing → vibration aging → semi-finishing → vibration aging → finishing, after tempering machining, To ensure the overall strength of the beam, rigidity and stability, long time to maintain the accuracy of beams.

Machine Configuratio

CNC Control Language:

Besides English, we have professional Russian, Spanish,German language, we can also support local agent to translate any language in need.

Laser Power Option:

IPG: 500W,700W, 1000W, 1500W, 2000W, 3000W, 4000W, 6000W

Trumpf : 2000W, 3000W, 4000W, 6000W

Raycus: 500W, 750W, 1000W, 1500W,3300W

Nlight:500W, 750W, 1000W, 2000W,1500W,3000W

MAX:500W, 750W, 1000W, 1500W,2000W,3000W

Machine size:

3015, 4015, 4020, 6015, 6020. 6023, 6025, 6525, 8020, 8025, 9520, 12025, 13030…..We customize as your metal sheet size.

Machine type:

Single table, All cover, All cover exchange platform etc.

Machine Warranty

Potència làser:

Two years warranty, Guaranteed by laser power manufacturer

YAHONG Machine Bed:

Ten years warranty, Guaranteed by YAHONG

Electronics and motion parts:

One year warranty, Guaranteed by parts manufacturer

Free Warranty Service:

We will send replacement parts on our cost first, keep customer's machine running is top concern.

If machine needs onsite service for quality issue, we send technician to anywhere on our cost. You may inquire any of our old international customers for reference!